-

Phone

-

Email

Rolling Mill

Four High Rolling Mill

These machine consist four rollers (two small and two big). These rollers are arranged as shown in figure. Small rollers are in direct contact with work piece and rotate in opposite direction. Big rollers works as backup rolls and they also rotates in opposite direction with each other and also with contact roller. This machine is used for cold rolling where high rigidity required.

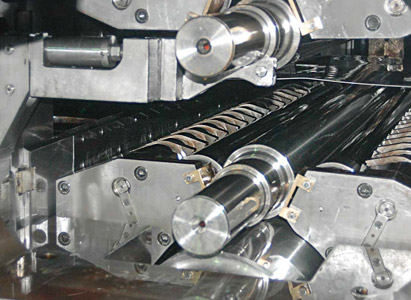

Tandem Rolling Mill

Tandem rolling is also known as continuous rolling in which two or more set of four high rolling mill arranged in a series in which each set is called stand. These stands are arranged so they can roll the work piece in decreasing cross section. It is used for rolling thick work piece in single pass.

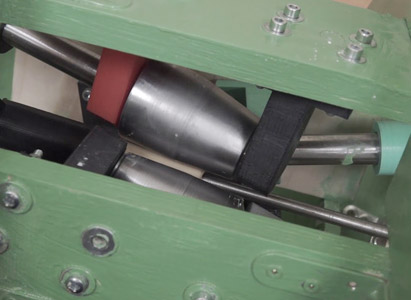

Cluster Rolling Mill

In this type of rolling mill, each of working roller is backup by two or more of larger backup roller. These rollers are arrange as shown in figure. This machine is used for rolling hard material.

Universal Rolling Mill

The universal rolling mill consists of two vertical rolls and two horizontal rolls. The vertical rolls are idle and are arranged between the bearing chocks of the horizontal rolls in the vertical plane. Universal rolling mills are used for producing blooms from ingots and for rolling wide-flange H-section beams.